The aim of the blade design and test programme is to develop a blade family for Orbital’s tidal technology with a rotor diameter of up to 26m (the maximum diameter that would be typically deployed on a tidal site).

To achieve this, it was decided to implement a full hierarchical test programme by scale of component from material coupon (Level 2), to sandwich panel (Level 3) to spar beam (Level 4) to full blade (Level 5). Level 1 pure material testing has previously been completed by Orbital.

The testing programme commenced in mid-2023. A key focus to date has been qualifying material systems for use in the blade, particularly in ensuring that adhesive systems in key areas of the blade are fully optimised for maximum performance.

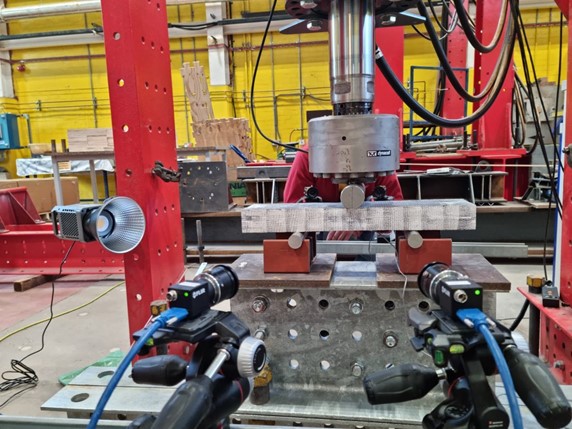

This has meant extensive laboratory testing of glass/carbon composite hybrid material systems with sophisticated structures which are differentiated for different segments of the blade. Tests have included tensile, compression, interlaminar shear and fatigue modes to determine all the associated properties and thereby establish fully de-risked design allowables for Orbital’s overall blade design.

In addition, several larger scale sandwich panels and beams have been tested to determine the scalability of the material properties established in the lab.

In 2025, Level 3 testing will commence. This will involves taking materials validated in Level 2 and fabricating larger structures to determine any effect of scale and geometry on the measured properties and performance of the laminates.

A large beam of composite, equivalent in scale and lamination to that to be ultimately used in the blade, will then be tested at FastBlade to understand the behaviour of the beam connection to the turbine in application and isolate certain behaviours that would be ‘disguised’ by other mechanical responses if a full blade were to be tested.

Finally, Level 5 testing towards the latter half of 2025 will involve the testing of a full-scale blade with all the key design features.

Contact

James Murray

Project Manager

j.murray@orbitalmarine.com