Optimisation is key to enable the tidal sector to make significant contributions towards Europe’s energy systems, energy security and industrial development by 2030, and beyond to 2050.

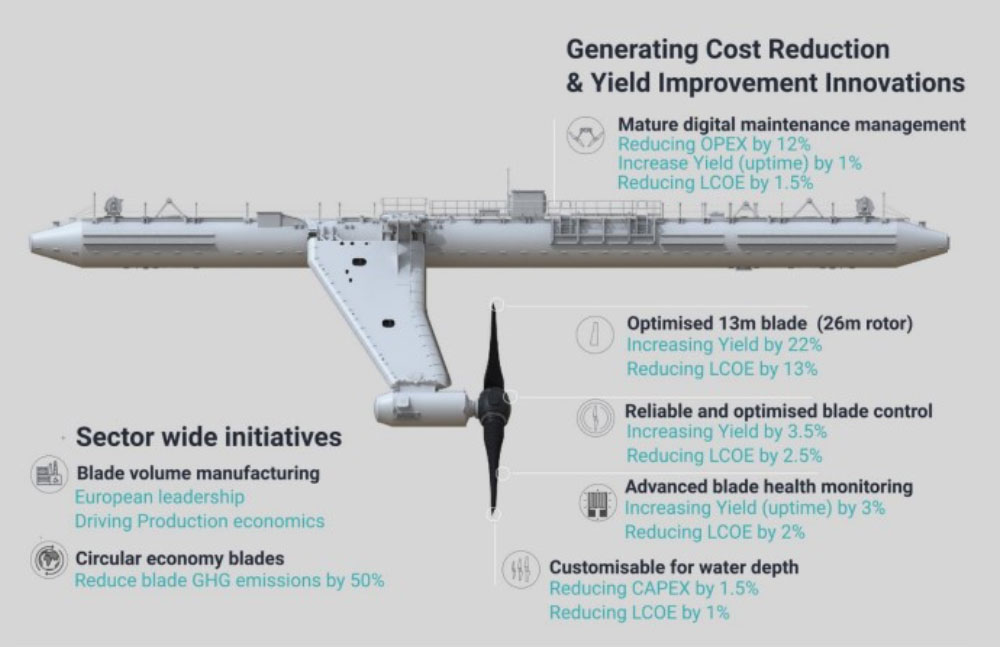

MAXBlade is a highly ambitious project designed to deliver the essential blade and rotor innovations needed to aggressively bring down the levelised cost of electricity (LCoE).

A suite of innovations will generate essential data across the entire life cycle of the tidal blades. Eight consortium partners – Orbital Marine Power, Marasoft, TECNALIA, University of Edinburgh, EMEC, ENGIE Laborelec, the European Composites Industry Association and TechnipFMC – will collectively research blade reliability, scale and recyclability, condition monitoring, control, integrated maintenance management, and knowledge capture methods.

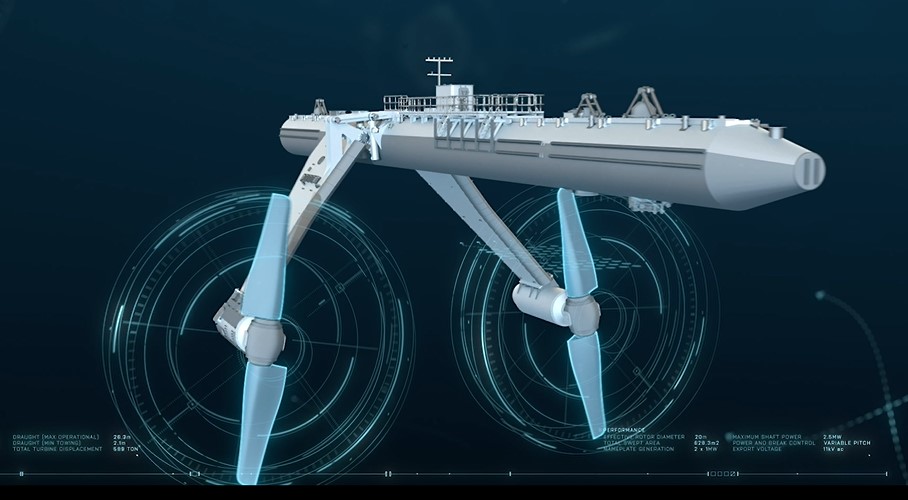

The single, biggest innovation the project seeks to deliver is an increase in rotor diameter from 20m to 26m. This will increase the area the blade can sweep by 70% – hugely improving tidal energy efficiencies.

Combined, these innovations seek to drive down tidal energy costs for volume manufacturing.

Project aim

Orbital’s tidal stream energy technology represents a disruptive approach to cost and MAXBlade aims to reduce LCOE by 20%.

Innovations in MAXBlade, alongside the system wide innovations of FORWARD-2030, will be combined in a core product which will:

- achieve aggressive cost reduction targets in line with the SET-Plan targets on ocean energy;

- support the financing of a number of targeted pilot tidal arrays; and

- support further cost reductions through volume manufacture.

Project objectives

Maximise project yield

through delivery of reliable, cost optimised and customisable 26m tidal turbine rotors.

Increase turbine availability

through development and implementation of advanced tidal blade structural condition monitoring.

Maximise array level power performance

through delivering of reliable control inputs and optimal blade and controller designs.

Enable circularity in tidal turbine blades

including recyclable thermoplastic manufacturing.

Secure European leadership

of tidal turbine composite blade manufacturing with competitive 320 tidal blade per annum capacity by 2030.

Advance integrated digital maintenance management of tidal arrays

Project background

The future commercial rollout of tidal stream energy, in line with the EU Offshore Renewable Energy Strategy and Strategic Energy Technology Plan (SET) targets, rests on five key pillars. MAXBlade has been developed to significantly advance these first three pillars with a focus on the full blade lifecycle, control, condition monitoring and asset management.

MAXBlade is a parallel, sister project to FORWARD-2030. It will run approximately 18 months behind FORWARD-2030 and be supported with operational data from FORWARD-2030 and the O2 tidal turbine.

Ability to approach cost competitiveness

with other low carbon technologies through aggressive technical innovation.

Addressing technology and component performance uncertainties

and mature asset management impacting the sector’s ability to raise affordable finance for wide scale rollout.

Cost reduction

through volume manufacturing and supply chain capacity.

A pipeline of deployment opportunities

Consenting and environmental impact uncertainties

Funding

This project has received funding from the European Union’s HORIZON-CL5-2022-D3-01-07